In the evolving world of modern engineering, manufacturing, and daily household innovations, the term laaster is gaining recognition for its versatile applications. A laaster generally refers to a supportive tool, device, or method used to enhance stability, assistance, and efficiency in practical tasks. Whether applied in industrial settings, mechanical engineering, or everyday problem-solving, laasters are indispensable in improving safety and performance.

This article explores the concept of laaster in depth—its definition, types, uses, and how it contributes to greater reliability and productivity across multiple sectors.

Understanding What a Laaster Is

At its core, a laaster functions as a stabilizing or assisting element designed to make tasks smoother and more precise. While the word itself can apply to several contexts, it often denotes a device or mechanism that offers support or reinforcement. From mechanical systems that require balance to electronic operations that demand efficiency, laasters have a broad range of purposes.

For example, in mechanical workshops, a laaster might refer to a supportive framework or jig that holds components firmly during assembly. In digital systems, the concept might extend metaphorically to software algorithms that optimize performance. Regardless of form, the central idea remains the same—enhancing stability and functionality.

The Role of Laaster in Industrial Applications

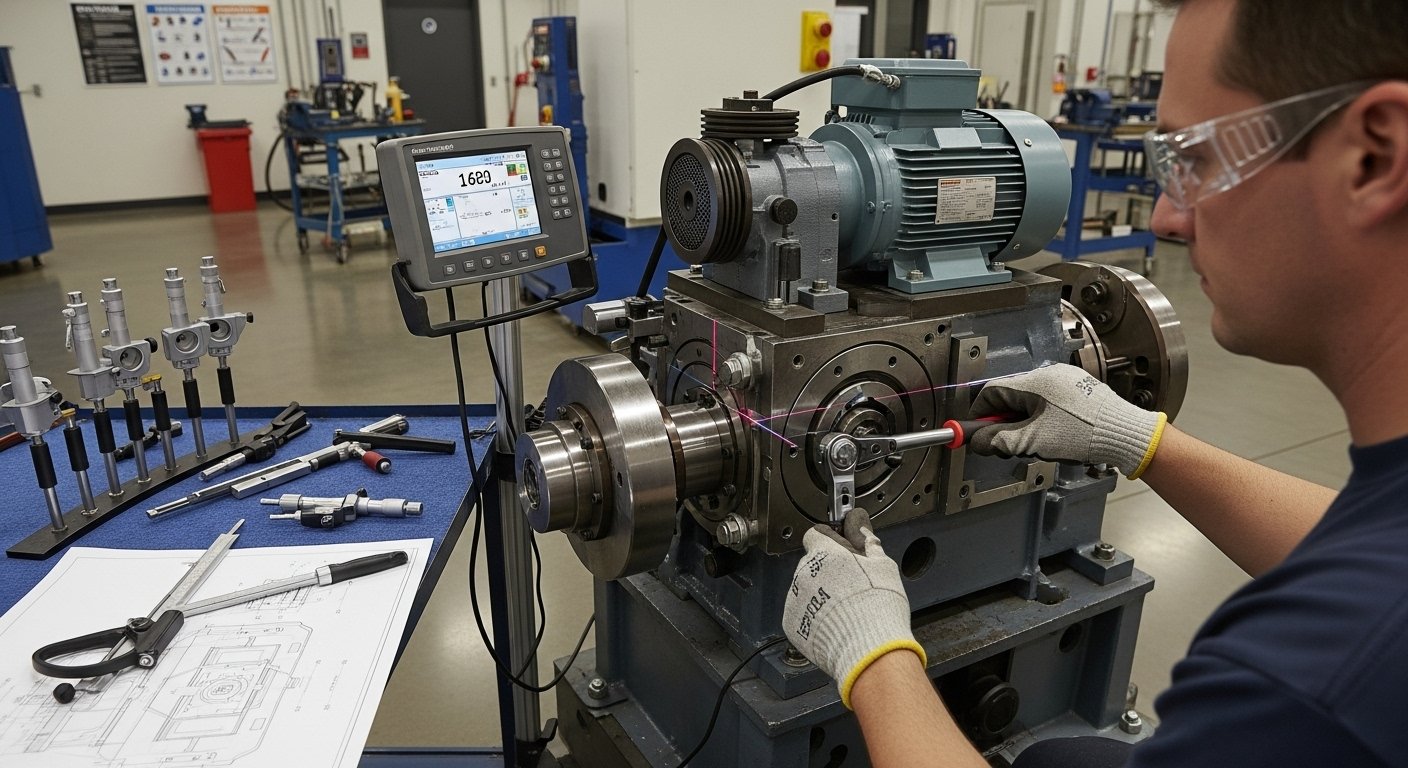

In industrial settings, precision and safety are paramount. Machines, tools, and operators must function in perfect harmony to maintain quality and avoid hazards. This is where a laaster becomes crucial.

Some industrial uses include:

- Assembly Line Support:

In manufacturing environments, a laaster may serve as a stabilizing arm or support frame that holds components steady during production. This minimizes vibration and ensures exact alignment. - Load Distribution Systems:

Heavy machinery and equipment often rely on laasters to distribute weight evenly, preventing undue stress on critical components and extending operational lifespan. - Calibration and Measurement:

Engineers use specialized laasters to position tools with microscopic accuracy. By maintaining fixed angles and support, these tools reduce human error and improve consistency.

Through these applications, the laaster acts not only as a support system but also as a quality assurance mechanism that upholds precision and safety.

Household and Everyday Uses of Laaster

Beyond the industrial sphere, the concept of laaster finds meaningful application in household and daily life. Many home improvement tools, gadgets, and ergonomic designs employ laaster principles to assist users in performing tasks more comfortably and effectively.

Some everyday examples include:

- Furniture Assembly Supports: Adjustable frames or clamps that hold furniture pieces in place can be considered laasters.

- Kitchen Tools: Devices such as adjustable cutting boards or stabilizing platforms used in cooking embody the laaster principle.

- Mobility Aids: Walking frames, hand supports, and other assistive devices provide physical stability—an essential function of a laaster.

These tools, though simple in design, embody the same philosophy: providing assistance to improve stability and efficiency.

The Technological Evolution of Laaster

As technology advances, the laaster concept continues to evolve. Modern innovations now incorporate smart sensors, AI algorithms, and automated feedback systems into laaster-based tools and equipment.

For example:

- Robotics and Automation: In robotics, laaster-inspired components help maintain balance and control during precision tasks.

- AI-Driven Assistance Systems: Digital laasters in software can automatically adjust settings for efficiency, such as load balancing in servers or workflow optimization tools.

- Smart Manufacturing: Factories now use robotic laasters to fine-tune production lines dynamically, adjusting tension, position, and speed based on real-time data.

These integrations illustrate how the once purely mechanical laaster has become a technological cornerstone of modern efficiency.

The Benefits of Using a Laaster

Implementing a laaster—whether physical or digital—brings numerous advantages. The most significant benefits include:

- Enhanced Stability:

Laasters reduce vibrations, displacement, and error margins in tasks requiring precision. - Improved Safety:

By providing firm support or automated corrections, laasters reduce the risk of accidents and operational failure. - Increased Efficiency:

Tasks are completed faster and with fewer interruptions when a laaster is integrated into the workflow. - Consistency and Quality Control:

A stable and reliable system yields consistent outcomes, essential for both industrial and household settings. - Reduced Fatigue and Effort:

In ergonomically designed applications, laasters minimize physical strain on users, leading to better productivity and comfort.

The combination of these factors makes laaster technology indispensable in modern work environments and personal life.

Types of Laaster

Depending on the field of use, laasters can be categorized into different types:

- Mechanical Laaster:

These include supports, brackets, clamps, and frames that physically stabilize materials or equipment. - Digital Laaster:

In computing, digital laasters can be algorithms or programs that stabilize performance, such as network balancing or error-correction software. - Ergonomic Laaster:

Devices designed to assist human motion or reduce strain—like adjustable workstations or posture aids—fall into this group. - Automated Laaster:

Equipped with sensors or robotics, automated laasters can self-adjust to maintain stability or efficiency in dynamic conditions.

Each category contributes uniquely to the overall goal of support, stability, and improved performance.

Laaster in Engineering and Construction

In engineering and construction, precision determines the success of any project. Laasters in this context serve as the backbone of alignment, measurement, and structural integrity.

Examples include:

- Support beams and stabilizers that hold structures during construction.

- Alignment jigs for welding or assembly.

- Temporary frameworks are designed to bear loads until permanent structures are secure.

Without such laasters, construction processes would face increased risk, errors, and inefficiency. The laaster ensures that every phase—from groundwork to finishing—remains stable and accurate.

The Future of Laaster Technology

Looking forward, the evolution of laaster will likely merge with AI, robotics, and sustainable engineering. Future laasters may become self-learning systems that detect imbalance, fatigue, or inefficiency in real time and adjust automatically.

Possible innovations include:

- AI-based predictive stabilization tools for machinery maintenance.

- Smart laaster exoskeletons to support workers during physically demanding tasks.

- Eco-friendly materials for lightweight, durable laaster frameworks.

These advancements will transform the laaster from a simple support tool into an intelligent partner in human and machine collaboration.

Challenges and Considerations

While laasters offer immense benefits, certain challenges must be addressed to maximize their effectiveness:

- Cost of Implementation: High-tech laasters with automation features can be expensive.

- Maintenance Needs: Regular calibration and upkeep are essential for mechanical or digital laasters.

- Compatibility: Integrating laasters into existing systems requires design precision and testing.

- Skill Requirements: Users must understand how to operate or maintain the laaster correctly to avoid inefficiencies.

Overcoming these challenges involves balancing innovation with practicality—ensuring laasters remain accessible, durable, and adaptable.

Conclusion

The laaster stands as a testament to human ingenuity—a simple yet profound concept that bridges the gap between stability, assistance, and efficiency. From its mechanical roots to its modern digital forms, the laaster has proven its value across industries and daily applications alike.

As technology continues to progress, the laaster’s role will expand beyond traditional support, becoming an integral part of intelligent systems that anticipate needs, correct deviations, and enhance performance autonomously.

In essence, the laaster is more than a tool—it is a philosophy of balance, precision, and progress that underpins the way we build, operate, and innovate in the modern world.